Konstante Qualitätssicherung garantiert höchste Qualität in Ihren Systemlösungen

Die Anforderungen unserer Kunden an die Qualität sind für uns das Maß aller Dinge.

Unsere Qualitätssicherung

Wir garantieren Ihnen konstante Qualität auf einem hohen Niveau. Als Dienstleister haben wir den Anspruch, für unsere Kunden echte Mehrwerte zu schaffen. Wir wollen die Anforderungen und Erwartungen unserer Kunden zuverlässig erfüllen und sogar übertreffen. Daher sichern wir bei sämtlichen Geschäftsprozessen die Qualität. In der Materialwirtschaft, beim Engineering, der Fertigung und der Logistik setzen wir die höchstmöglichen Gütemaßstäbe an.

Qualität muss objektiv nachweisbar sein. Unter der Anwendung erprobter Messtechniken und mit einem zeitgemäßen, professionell ausgestatteten Messraum generieren wir daher präzise Prüfergebnisse und dokumentieren diese sorgfältig. Den Erwartungen unserer Auftraggeber bezüglich eines umfassenden Qualitätsmanagementsystems wollen wir vollumfänglich gerecht werden. Qualität definiert sich aus der Perspektive unserer Kunden. Der Kundenwunsch ist unser Antrieb in der täglichen Arbeit. Das Wort Problem haben wir aus unserem Wortschatz verbannt, wir finden gemeinsam immer eine Lösung.

Ihre Vorteile durch unsere Qualitätssicherung im Überblick

- Feinmessraum der Messraumklasse 1 (±0,4 °C/24 Std.)

- Messmittelüberwachung – regelmäßige Wartung und Kalibrierung der Prüf- und Messmittel

- Lohnmessung gegen Zeichnung

- Inklusive Prüfprotokolle und Dokumentationen zu Ihrer Messung

- 3D-Daten in STEP einlesbar

- Optische Lohnmessung

- Erstbemusterungen, Spektralanalysen

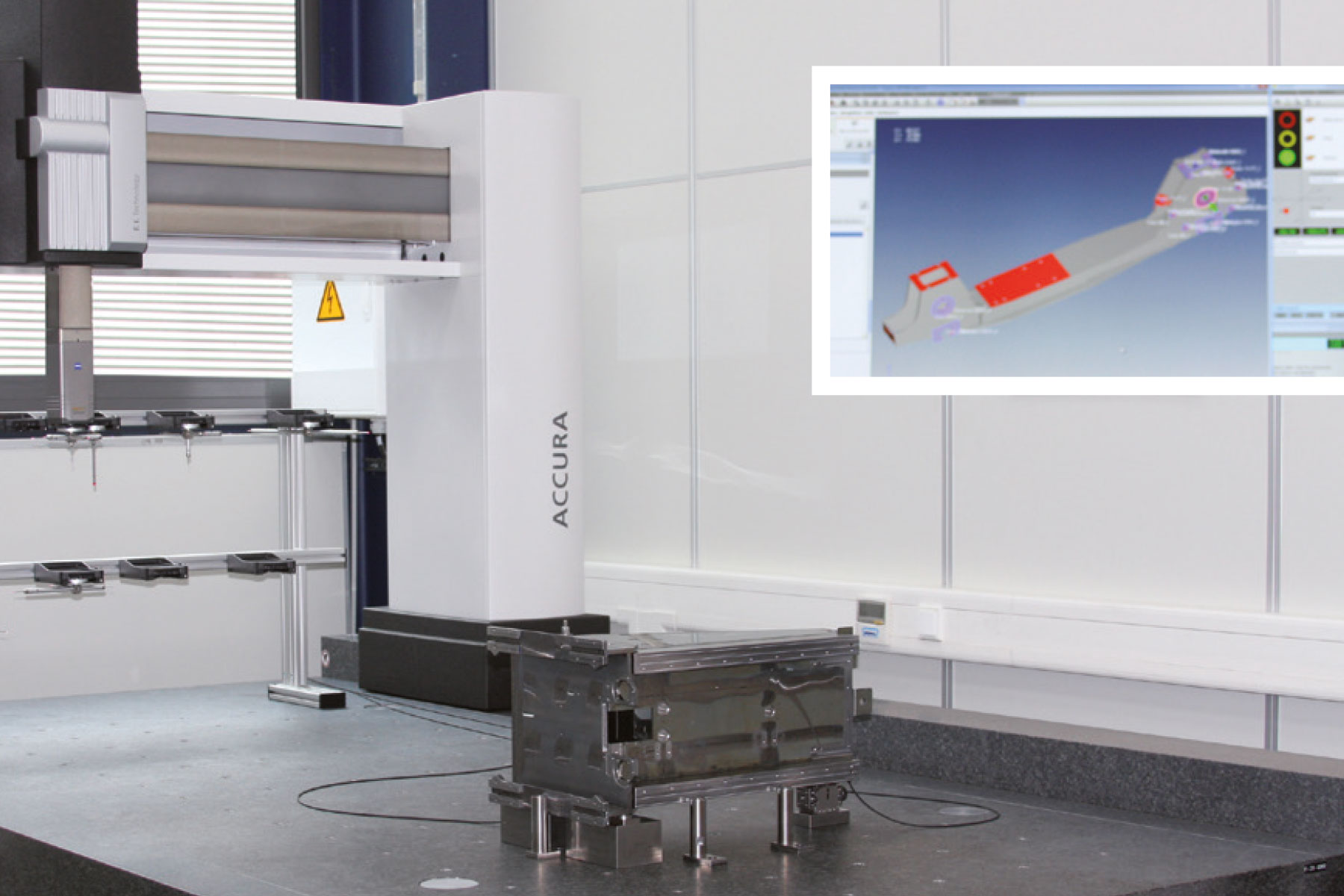

3D-Koordinatenmessgerät

Zeiss ACCURA II

10 VAST gold

Messbereich:

X = 1.200 mm

Y = 3.000 mm

Z = 1.000 mm (abzüglich verwendeter Tasterlänge)

Längenmessabweichung nach ISO 10360-2 E0:

(1,9 + L/300) µm, PFTU = 1,9 µm

Software:

Basissoftware Calypso

3D-Koordinatenmessgerät

Wenzel LH87

Messbereich:

X = 800 mm

Y = 1.700 mm

Z = 700 mm (abzüglich verwendeter Tasterlänge)

Längenmessabweichung:

(3,5 + L/200,0) µm

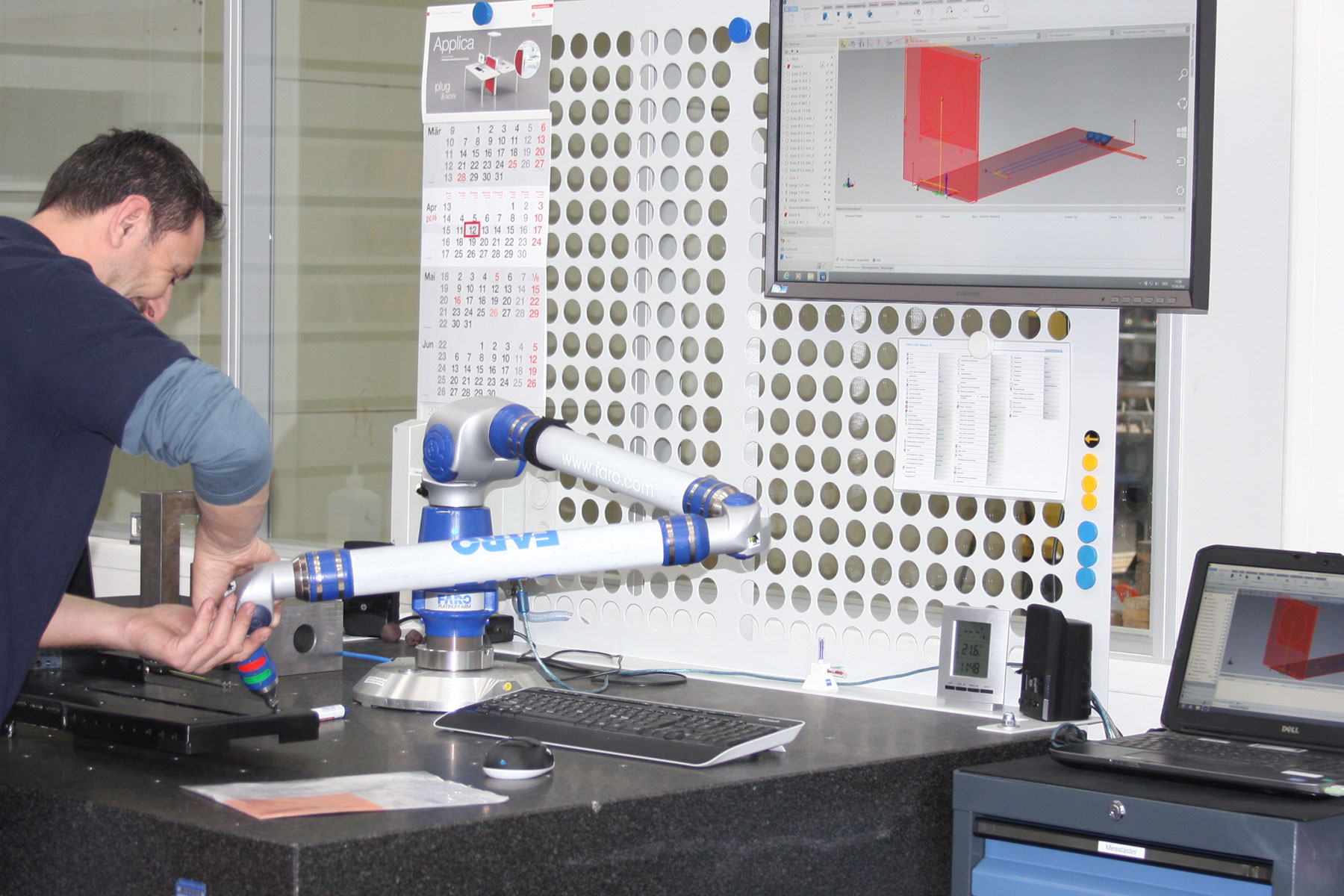

Portable Messeinrichtung

FARO Platinum Messarm

Messbereich: 2.400 mm

Messgenauigkeit: 0,025 mm

Messbereich: 1.200 mm

Messgenauigkeit: 0,013 mm

Software:

CAM2 Measure 10.4

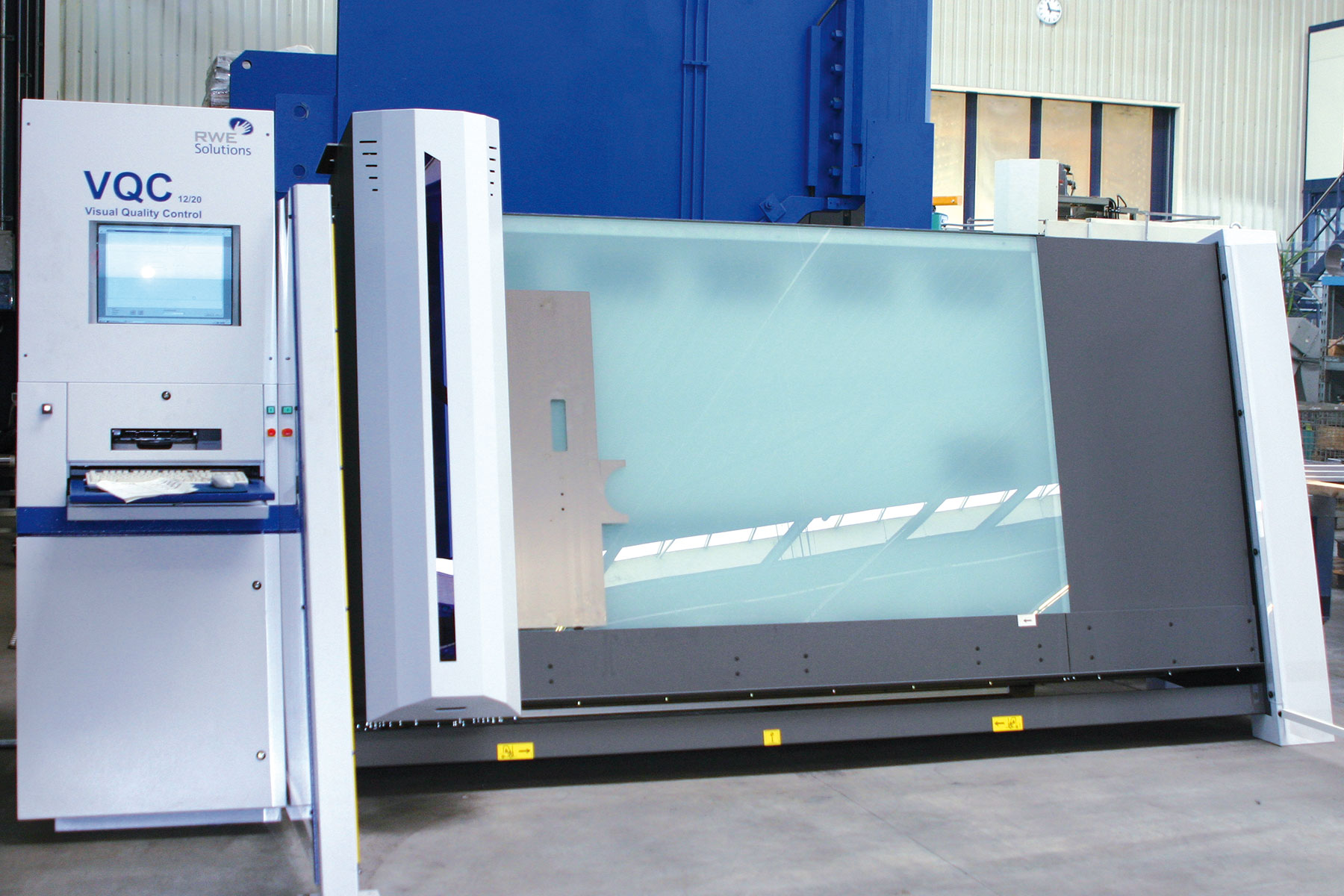

Optische Messeinrichtung

VQC Scanner Platinenscanner

Messbereich:

1.200 x 2.000 mm

Messgenauigkeit:

0,05 mm

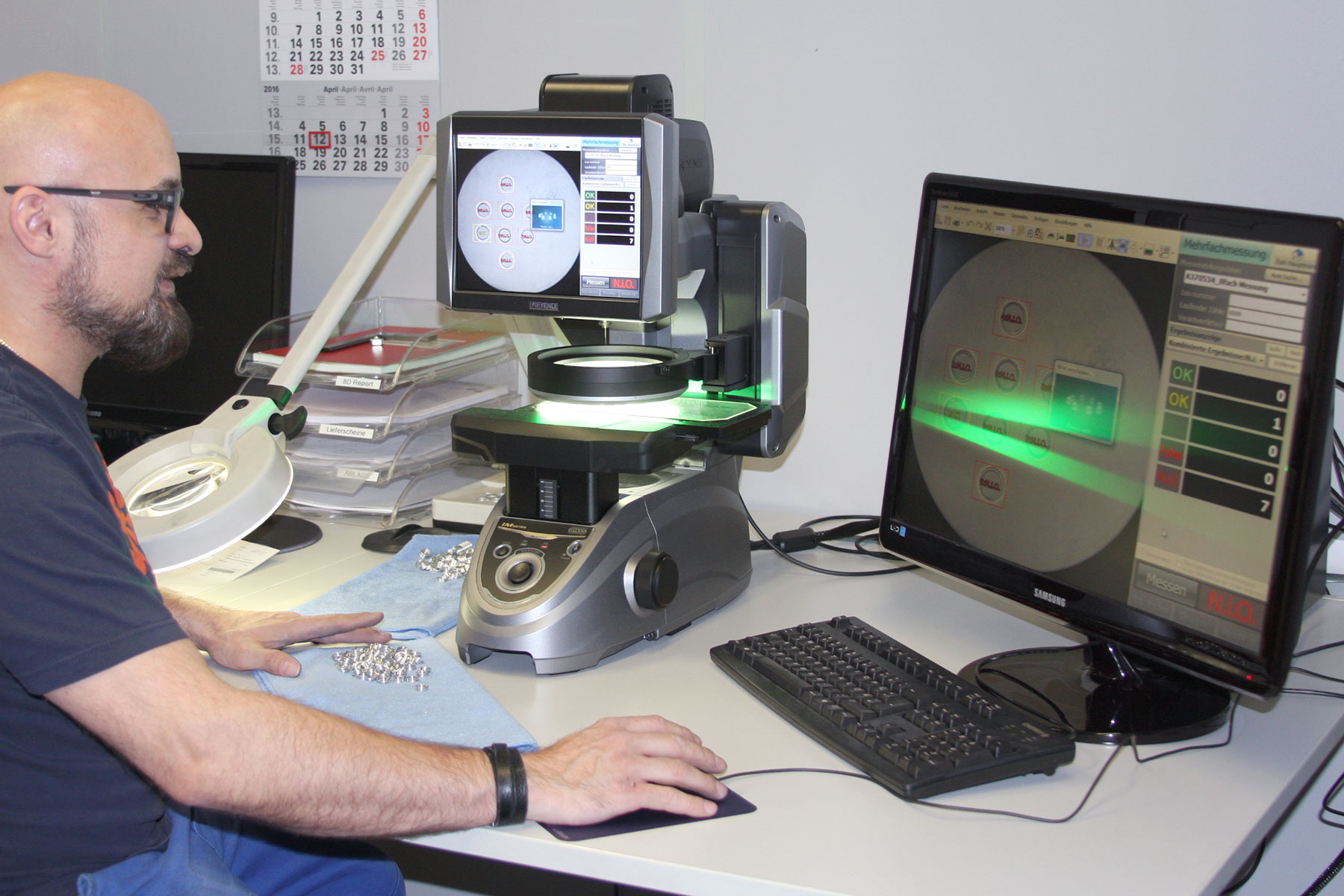

Optische Messeinrichtung

Digitaler Messprojektor KEYENCE

mit Höhenmessung

Messbereich: 100 x 200 mm

Messgenauigkeit: ±1 µm, 25 × L125 mm

Bildfeld: ±0,5 µm

Unsere Mitarbeiterinnen und Mitarbeiter sichern unsere Qualität

Bei der H.P. Kaysser GmbH + Co. KG sind inzwischen mehr als 450 Mitarbeiterinnen und Mitarbeiter angestellt. Unsere Beschäftigten unterstützen wir selbstverständlich in ihrer Weiterentwicklung. Im Sinne der Qualitätsorientierung und der individuellen Aufstiegsmöglichkeiten erhält unser Fachpersonal Zugang zu regelmäßigen Fortbildungen. Unsere Führungskräfte informieren nicht nur die Belegschaft über die qualitativen Anforderungen, sondern leben das Bewusstsein für Struktur-, Prozess- und Ergebnisqualität auch vor. Daher arbeiten all unsere Mitarbeiterinnen und Mitarbeiter qualitätsorientiert und haben Freude an der Auswertung von Messdaten sowie der Beteiligung an internen Audits. Unseren Kunden geben wir ein umfassendes Qualitätsversprechen. Als zusätzliche Dienstleistung bieten wir Ihnen die Lohnmessung Ihrer Bauteile an.

Auch beginnen jedes Jahr rund 35 junge Menschen bei der H.P. Kaysser GmbH + Co. KG ihre Ausbildung für technische und kaufmännische Berufe. Wir bieten begabten Nachwuchskräften eine langfristige Perspektive. Eine solche Kontinuität hilft uns, die unternehmerische Performance auf einem hohen Qualitätslevel zu halten.

Wir versprechen Ihnen erstklassige Servicequalität

In unserem Qualitätsversprechen ist auch der Service eingeschlossen. Wir bietet Ihnen Fertigungen rund um die Uhr. Unsere Organisation ist so ausgerichtet, dass wir Aufträge schnell, zuverlässig, flexibel und bei Bedarf auch am Wochenende fertigstellen können. Unsere Industriekunden sparen dadurch wertvolle zeitliche Ressourcen. Aufgrund unserer agilen Strukturen können wir Klein- und Mittelserien bis zu einer Stückzahl von mehreren Zehntausend pro Jahr umsetzen. Termintreue und der möglichst kostengünstige Versand zum Bestimmungsort sind für uns eine Selbstverständlichkeit.

Sie wünschen weitere Informationen?

Bitte teilen Sie uns Ihren Namen und Ihre Telefonnummer mit, wir rufen Sie gerne an.

Für eine ausführliche Anfrage nutzen Sie bitte unser Kontaktformular.